Fixed Ammonia Gas Detectors Applications

Ammonia gas detectors are important safety protection equipment to ensure the safety of the workplace, because strongly smelling ammonia can become toxic when exposed to air.

Ammonia gas detectors are important safety protection equipment to ensure the safety of the workplace, because strongly smelling ammonia can become toxic when exposed to air.

Ammonia gas detectors are important safety protection equipment to ensure the safety of the workplace, because strongly smelling ammonia can become toxic when exposed to air. Continuous monitoring of ammonia concentrations in the air can reduce irritation to the skin, eyes, nose and throat and even help prevent respiratory failure.

Fixed gas detection utilizes electromechanical sensors that feature a liquid electrolyte. As ambient air passes through the sensor, electrodes within the electrolyte produce a current that digitizes the flow to produce a measured value that is transmitted as an analog signal. When levels reach a concentration higher than what is allowed per safety regulations, the ammonia gas sensor triggers a warning signal or alarm.

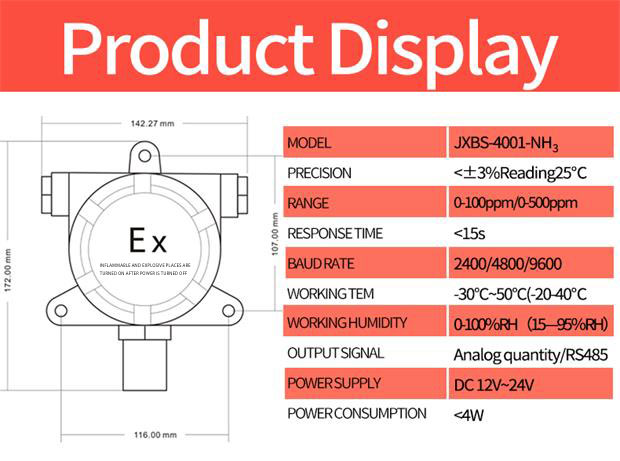

JXCT has been a global leader in fixed gas detection and alarm control since 2015. Our line of ammonia gas detectors and sensors provide the price/performance ratio and versatility to fit any situation. Ammonia gas detectors and monitors offer important features including sensor heater for low-temperature applications such as ammonia refrigeration, Ethernet with embedded Web Server, and wireless ammonia monitoring with the easy to install. Our 4-20mA loop-powered ammonia (NH3) gas detectors and monitors offer the same reliability, but at a lower price point.

Selecting the correct sensor for your application can be confusing. The professionals at JXCT have years of experience monitoring ammonia and other toxic gases. Please reach out to us for help selecting the best products for your specific application.

Proper placement of the ammonia gas sensor is important for it to be effective. Since ammonia gas is lighter than air, it will typically rise to the ceiling when it is released. Placing ammonia gas sensors at ceiling height will help ensure that leaks are detected before they reach dangerous levels. If they are placed too low in the room, the ammonia gas sensors will take much longer to detect the gas, allowing it to accumulate and cause respiratory irritation.

When installing ammonia gas sensors for fixed gas detection, it is important to avoid placing the detectors near windows, vents, or fans. Installation near drafts or circulating air will prevent the sensor from getting an accurate reading, making the device less effective. Humidity and temperature are also important, as hot or humid conditions can affect the accuracy of readings. If your operating environment is humid or the ammonia gas sensor will be exposed to high temperatures, the use of protective heat shields may be required.

For effective ammonia gas detection, you also need to have enough sensors to provide enough coverage for your room size. Our experts can help you determine how many ammonia gas sensors you need based on your facility size, ammonia equipment size, and type of sensor selected.

Ammonia gas sensors should be tested monthly, at a minimum, to ensure they are functioning properly. These tests, known as bump tests, involve briefly exposing the sensor to ammonia gas to see if it responds. If the ammonia gas sensor does not trigger an alarm after exposure, the device will need to be calibrated. To calibrate the anomia gas sensor, the device is subjected to prolonged exposure to ammonia gas. During this time, the readings provided by the sensor are monitored to ensure accuracy.

The date the testing took place, as well as the results, should be recorded as part of your fixed gas detection preventative maintenance plan. Maintenance and calibration can be performed by a facility manager, or by a local gas detection expert. Contact our support team to learn more about monitoring ammonia levels at your facility.