Fixed Gas Detectors: The Key to Safe and Efficient Operations

To ensure safe and efficient operations, many companies rely on fixed gas detectors.

To ensure safe and efficient operations, many companies rely on fixed gas detectors.

In industrial settings, the presence of gas is often a fact of life. Whether it's natural gas, methane, carbon monoxide, or another potentially hazardous substance, workers and facility managers must be vigilant to detect gas leaks or accumulation, which can lead to dangerous situations such as explosions, fires, or asphyxiation.

To ensure safe and efficient operations, many companies rely on fixed gas detectors. These devices are designed to monitor the air in a particular area and detect the presence of specific gases, alerting workers and managers to potential hazards so that they can take immediate action.

Fixed gas detectors are an essential tool for any facility where gas is present. They offer a reliable and continuous means of monitoring the air, providing early warning of any dangerous gas leaks or accumulation.

Without fixed gas detectors, workers may be unaware of the presence of gas until it is too late, putting their safety and the safety of the facility at risk. Additionally, gas leaks or accumulation can cause damage to equipment and infrastructure, leading to costly repairs and downtime.

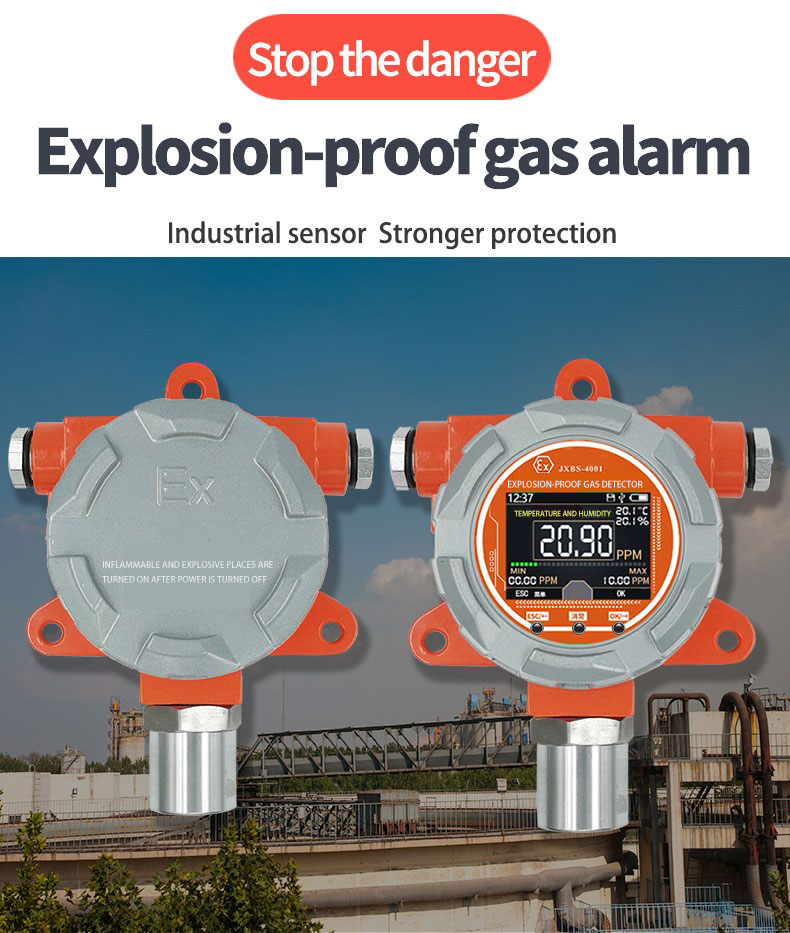

Fixed gas detectors help to prevent these situations by providing a reliable and accurate means of monitoring the air. They can be used in a variety of settings, from manufacturing facilities to oil and gas refineries, chemical plants, and more.

Fixed gas detectors operate using a variety of technologies, including electrochemical, catalytic, infrared, and photoionization detection. Each type of detector is designed to detect specific types of gases, such as combustible gases, toxic gases, or oxygen depletion.

Electrochemical sensors work by converting the gas being detected into an electrical signal, which is then measured by the detector. Catalytic detectors use a heated wire to catalyze the gas being detected, causing a reaction that produces a signal.

Infrared detectors use infrared light to detect the presence of gas, while photoionization detectors use ultraviolet light to ionize gas molecules, producing a signal that can be detected.

Regardless of the type of detector used, fixed gas detectors are typically installed in strategic locations throughout a facility, such as near gas storage tanks or pipelines, and in areas where gas may accumulate, such as confined spaces or low-lying areas.

There are numerous benefits to using fixed gas detectors in an industrial setting. Some of the most significant advantages include:

Increased Safety: Fixed gas detectors provide a reliable and continuous means of monitoring the air for potentially hazardous gases, helping to prevent accidents and protect workers from harm.

Reduced Risk: By detecting gas leaks or accumulation early, fixed gas detectors can help reduce the risk of explosions, fires, or asphyxiation.

Improved Efficiency: By alerting workers and managers to potential hazards, fixed gas detectors can help to minimize downtime and keep operations running smoothly.

Compliance: Many industries are subject to regulations and standards related to gas monitoring and safety. Fixed gas detectors can help companies meet these requirements and avoid penalties or fines.

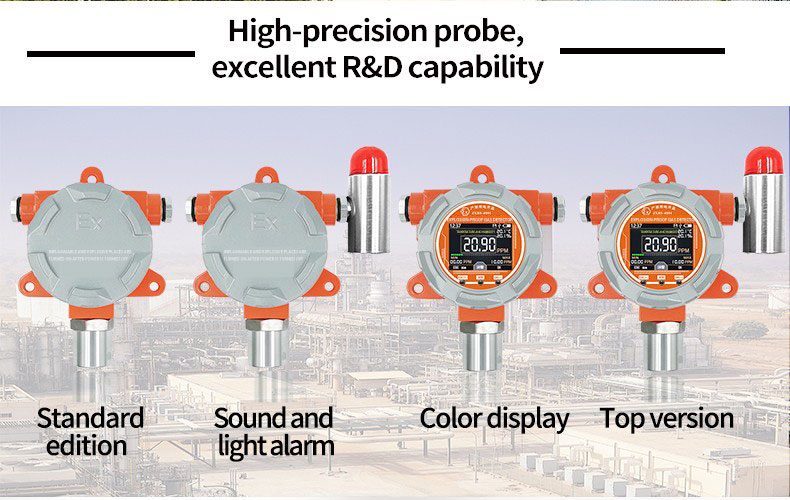

When selecting a fixed gas detector, there are several factors to consider, including:

Type of Gas: The detector must be able to detect the specific gas or gases that may be present in the facility.

Detection Range: The detector should be able to detect gas concentrations within the range required by the facility.

Operating Environment: The detector should be able to operate effectively in the environment where it will be installed, such as in high-temperature or high-humidity areas.

Maintenance Requirements: The detector should be easy to maintain and calibrate, with minimal downtime required.

Cost: The cost of the detector and its installation should be considered in relation to the benefits it will provide.

In addition to these factors, it is essential to work with a reputable and experienced supplier who can help select and install the right fixed gas detector for the facility's needs. They can also provide ongoing maintenance and support to ensure that the detector continues to operate effectively and efficiently.