Water quality sensor in industrial wastewater treatment

In order to establish a good ecological environment, industrial wastewater treatment monitoring is particularly important, can use water quality sensor to detect.

In order to establish a good ecological environment, industrial wastewater treatment monitoring is particularly important, can use water quality sensor to detect.

With the rapid development of industry, the quantity and type of waste water are also increasing, water pollution is becoming more and more serious, posing a serious threat to human safety and health. In order to establish a good ecological environment, industrial wastewater treatment monitoring is particularly important, can use water quality sensor to detect.

The serious contradiction between supply and demand of water resources is mainly manifested in the shortage of water resources and the continuous increase of water demand. In this context, the recycling of water resources is the main way to solve the contradiction.

The development of industrial wastewater treatment industry in China started late and entered the period of rapid development after 1990. With the growing demand for industrial wastewater treatment market in China, the current growth rate of wastewater treatment industry is much higher than that of other countries.

With the rapid development of China's industry, industrial waste water is increasing and environmental pollution is becoming more and more serious. Monitoring is one of the important links to control and control environmental pollution. The pH value, conductivity,COD(chemical oxygen consumption),BOD(biochemical oxygen demand),DO(dissolved oxygen),TOC(total organic carbon),TOD(total oxygen demand), toxic heavy metals such as lead, cadmium, zinc and cyanide, arsenic and fluoride in wastewater are all required testing items. This paper mainly introduces the water quality sensor in industrial wastewater treatment.

In Germany, industrial wastewater treatment must comply with the strict regulations of the Wastewater Regulation (Abwasserverordnung). Improper, inadequate handling can result in the entire plant shutting down until defects are corrected.

Treating industrial waste water goes far beyond complying with environmental regulations. Water-intensive factories reduce feedstock costs by treating and reusing waste water.

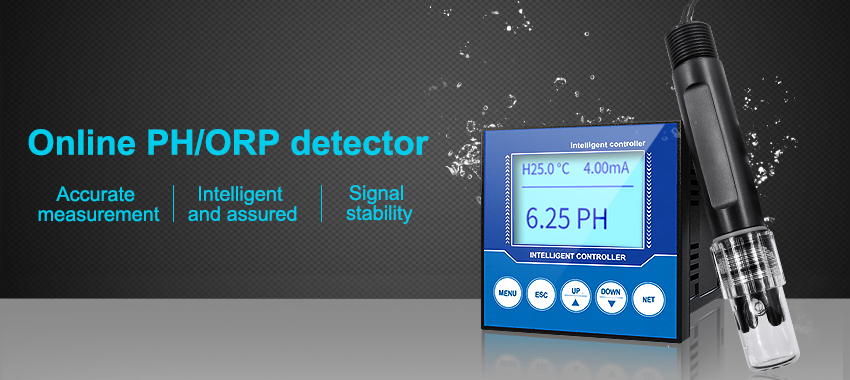

For organic wastewater treatment in particular, accurate measurements of pH, REDOX potential (ORP) and dissolved oxygen are critical to ensure optimal metabolism of bacteria used for purification.

Monitor pH, ORP and oxygen to achieve environmentally sound wastewater treatment

Unlike service water in private homes, industrial waste water is contaminated with substances that are difficult to break down. Depending on the industry, they may be heavy metals, grease, grease, alkaline substances, or, as in the paper and soap industries, organic substances can only be neutralized or separated with great effort. In addition to mechanical filtration methods, heat treatment and microorganisms are also used to purify it.

Depending on the degree of contamination, organically contaminated wastewater goes through various purification processes, including flocculation and precipitation. During flocculation, the dissolved hazardous material condenses into thin sheets that can be filtered. The goal of precipitation is to recombine harmful substances into heavier compounds before drifting down to the bottom. If the treated wastewater cannot be classified as harmless, the bacteria convert the remaining pollutants into flammable or recyclable biomass in the aeration tank.

Industrial water or clean water from food and beverage production or fermentation processes has a highly variable pH, depending on the application. Because low pH can damage plant components or kill bacterial cultures, recording the pH in the feed line is a timely countermeasure. Too high or too low pH can be neutralized by adding chemicals or, if necessary, interrupting wastewater entering the clarification tank. Due to its size for extreme pH values, JXCT's family of water quality PH sensor (Modular pH Sensor Platforms) is ideal for wastewater monitoring in the food and beverage industry. Modular pH sensor all materials are made of corrosion resistant materials, with strong corrosion resistance is widely used in process technology and monitoring, papermaking, plastic chemical industry, calcination plant, water treatment, sewage, cooling water and other industries.

Raw water in pharmaceutical industry mainly includes purified water and water for injection. Purified water or water for injection also ionizes to some extent, producing hydrogen and hydroxide ions that, although very weak in conductivity, have a measured conductivity.

Conductivity is an indicator of contamination of all ionic contaminants in pharmaceutical water, but it does not identify which ions, so in most applications, conductivity is used to reflect the purity of pure water.

People have been studying the conductance of sea water for nearly a hundred years, mainly focusing on the practical aspect -- using the conductance of sea water to measure the salinity of sea water. Because sea water is a multicomponent electrolyte solution, the conductivity of sea water depends on salinity, temperature, and pressure. Under the condition of constant temperature and pressure, the difference of electrical conductivity reflects the change of salinity. Based on this principle, the salinity of sea water can be calculated by measuring its electrical conductivity

The conductivity of pharmaceutical water is usually used in units of μS/cm, conductivity cell constant of 0.01 ~1.0cm-1 conductivity sensor. The conductivity cell constant depends on the geometry of the sensor and is the effective cross sectional area between the two plates divided by the distance between the plates. Conductivity cell constant is the main calibration parameter of conductivity measurement. In the use of online conductivity, the international use of μS/m as the unit of online conductivity value, 1μS/m is equivalent to 0.01μS/cm. The conductivity of ultra-pure water is 0.055μS/cm at 25℃. The conductivity of typical pharmaceutical water is 0.3~5μS/cm at 25℃. JXCT conductivity sensor features: According to the data recorder or remote sensing instrument (RTU) scaling, measuring the conductivity, total dissolved solids (TDS) or salinity 4 battery electrodes, auxiliary 0 to 50 ° C temperature sensor, 2 wire system, the water quality sensor is widely used in industrial waste water, waste water treatment, environmental remediation, groundwater monitoring, salt water intrusion, farmland runoff, mining pollution, aquaculture.

Dissolved oxygen (DO) is the amount of oxygen dissolved in water, expressed in milligrams of oxygen per liter of water. Oxygen dissolved in water is called dissolved oxygen, which exists in water in a molecular state. Dissolved oxygen in water is one of the important indicators of water quality, but also one of the important factors of water purification, high dissolved oxygen is conducive to the degradation of various pollutants in the water, so that the water can be quickly purified; On the contrary, the dissolved oxygen is low, and the degradation of pollutants in water is slow.

Generally, dissolved oxygen content in water is affected by two kinds of effects: one is the oxygen consumption that makes DO decrease, including the oxygen consumption of aerobic organic matter degradation and biological respiration; The other is the reoxygenation that increases DO, mainly the dissolution of oxygen in the air, photosynthesis of aquatic plants and so on. The mutual fluctuation of these two effects makes the dissolved oxygen content in water change in time and space.

When water is polluted by organic matter, it is oxidized by aerobic bacteria and consumes the dissolved oxygen. If the oxygen in the air is not timely replenished, then the dissolved oxygen in the water is reduced, eventually leading to water deterioration. So take dissolved oxygen as an index of water pollution degree. The less dissolved oxygen, the more serious the pollution.

Therefore, in the process of industrial water pollution control, wastewater biological treatment and aquaculture industry, the determination of dissolved oxygen is a big demand. JXCT's dissolved oxygen sensor, according to the included data logger, measures 0-20 mg/L or percentage saturation of dissolved oxygen electrode, insulated to prevent grounding loop, auxiliary 0-50°C temperature sensor, 2-wire, 4-20 mA analog output, compatible with wide range data logger or telemetry instrument, low power consumption; The water quality sensor is widely used in industrial wastewater monitoring, wastewater treatment, environmental monitoring, aquaculture.